A Practical Guide to PP Hollow Sheets: Structure, Styles, and Applications

PP hollow sheets—also known as PP corrugated sheets or twin-wall polypropylene boards—are lightweight plastic panels made by extruding polypropylene (PP) into a hollow, rectangular-core structure. These sheets are valued for their strength-to-weight ratio, water resistance, and reusability, making them a popular eco-friendly alternative to cardboard, foam, and even wood in many industries.

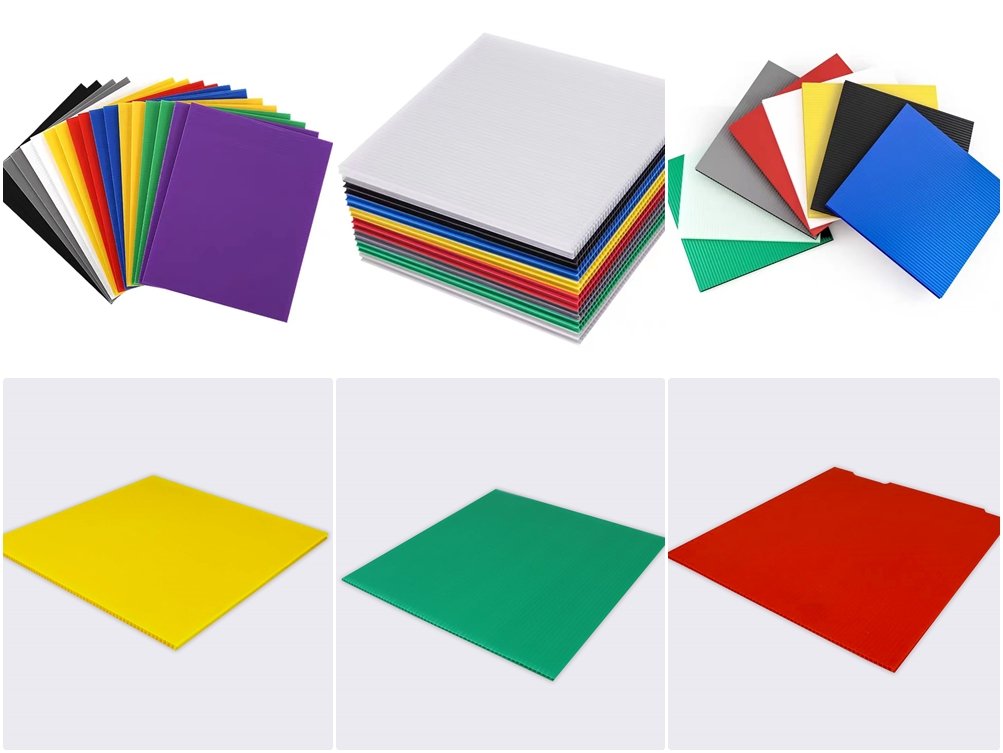

Widely used in packaging, logistics, signage, and temporary construction, PP hollow sheets come in a variety of styles based on thickness, color, surface texture, and functional additives.

What Makes PP Hollow Sheets Unique?

Made from thermoplastic polypropylene, PP hollow sheets offer excellent toughness and chemical stability. Unlike solid plastic or foam boards, their unique flute (or cell) structure gives them superior impact resistance while keeping the material lightweight.

These sheets can also be modified during production by adding UV stabilizers, flame retardants, anti-static agents, or conductive compounds—extending their use across a wide range of professional and industrial applications.

Common Styles and Variants

1. Standard PP Corrugated Sheet

Used for everyday transport packaging, layer pads, file folders, and basic box structures. Typically available in 3mm–5mm thickness and in standard colors like blue, white, and black.

2. Antistatic or Conductive PP Sheet

Formulated with carbon black or anti-static agents, these sheets have a surface resistance of 10⁶–10⁹ ohms. Ideal for electronics packaging, component trays, or ESD-sensitive areas.

3. UV-Resistant Outdoor Grade

Designed to withstand prolonged sunlight exposure, these sheets are ideal for outdoor signage, construction site barriers, or agricultural partitions. UV stabilizers help prevent yellowing or brittleness.

4. Flame-Retardant PP Hollow Board

With fire-resistant additives, these sheets meet flame-retardant standards such as UL94 V-2 or V-0. They are used in factories, renovation projects, and public installations.

5. Custom Flute and Reinforced Styles

In addition to the standard rectangular flutes, reinforced designs with thicker walls or ribbed structures provide improved bending strength and better water resistance. Flute size and orientation can also be customized.

Applications Across Industries

Packaging & Logistics: Used for returnable boxes, partitions, pallets, and fruit/vegetable crates. Lightweight and durable, they help reduce transport and storage costs.

Advertising & Printing: Serve as cost-effective signboards, display panels, and point-of-purchase displays. Compatible with screen printing and UV flatbed printing.

Construction & Decoration: Used for temporary site barriers, protective wall coverings, and floor protection. Easy to install and weather-resistant.

Agriculture: Ideal for nursery trays, greenhouse dividers, and planting boxes due to their resistance to moisture and soil.

Office & Daily Use: Applied in document holders, storage bins, DIY materials, and craft projects thanks to their ease of cutting and shaping.

Advantages of PP Hollow Sheets

Lightweight yet Durable: The hollow core reduces material weight while maintaining strength.

Waterproof and Chemical-Resistant: Polypropylene resists moisture, oils, and most chemicals.

Environmentally Friendly: Fully recyclable and reusable, supporting sustainable production practices.

Customizable: Color, thickness, flute size, and performance additives can be tailored for specific needs.

Cost-Effective: Offers longer life and multiple-use cycles compared to cardboard or disposable packaging.

What to Consider When Buying

When choosing a PP corrugated sheet, pay attention to thickness, grammage (weight per square meter), flute structure, and whether any special performance is required—such as antistatic, fire resistance, or UV stability.

For electronics or ESD packaging, select antistatic versions. For outdoor or sun-exposed applications, UV-resistant sheets are a must. For heavy-duty or stacking use, opt for thicker sheets with reinforced flute designs.

Conclusion: A Smart, Versatile Material for Modern Applications

Thanks to its light weight, high durability, and recyclability, PP hollow sheet is a reliable choice in industries that demand both practicality and sustainability. Its structural versatility, paired with the ability to tailor color, strength, and surface function, makes it ideal for everything from temporary signage to industrial packaging. Selecting the right type and configuration helps reduce material waste and improve performance—an ideal balance of efficiency, cost control, and eco-conscious design.